How to Maintain a Cold Room:

A Step-by-Step Guide to Troubleshooting Common Problems

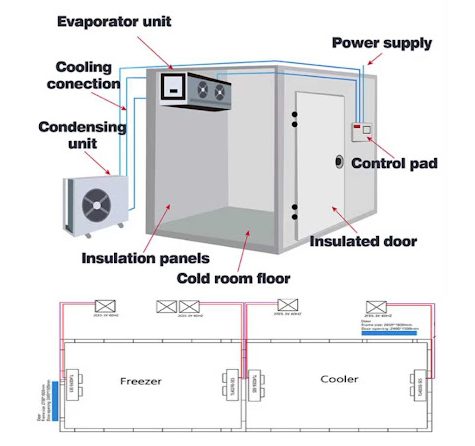

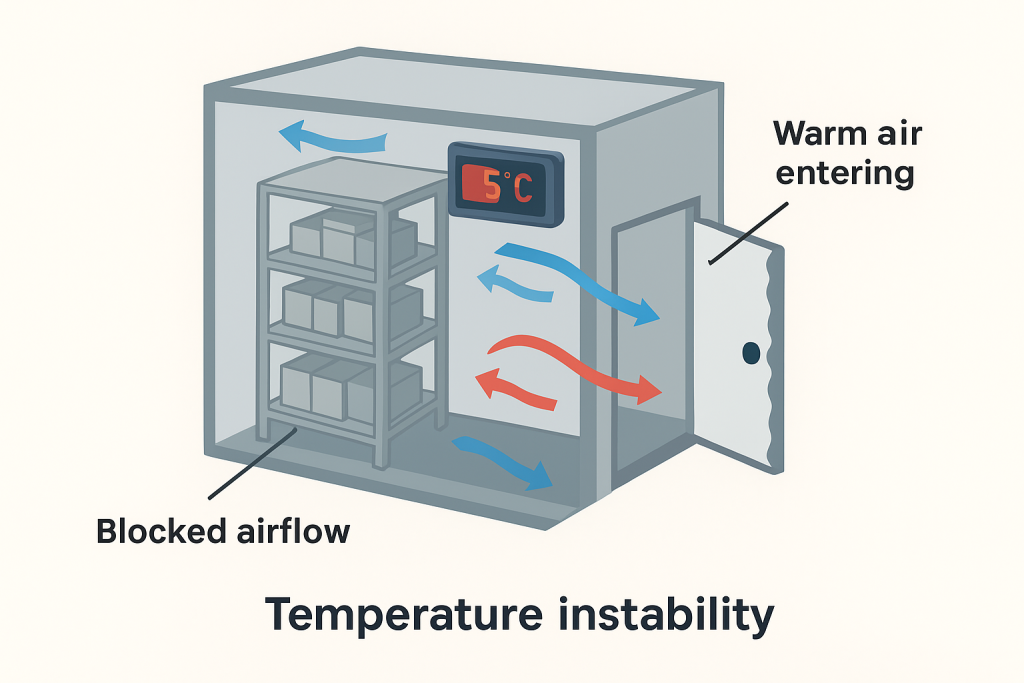

Operating a cold room is a cornerstone of businesses dealing with perishable goods, from restaurants preserving fresh produce to pharmaceutical warehouses safeguarding life-saving medications. A cold room’s reliability hinges on meticulous maintenance to prevent issues like temperature swings, frost buildup, or refrigerant pressure problems that can jeopardize product quality, inflate energy costs, and lead to costly repairs. Neglecting these systems risks spoilage, regulatory violations, and unexpected downtime, which can cripple operations.

This comprehensive guide dives deep into the world of cold room maintenance, offering actionable insights drawn from industry expertise. We’ll explore the most common challenges—temperature fluctuations, icing, and pressure issues—providing detailed troubleshooting steps and practical fixes you can perform without a technician. We’ll also outline structured servicing routines for before, during, and after use, alongside strategies to extend the lifespan of your equipment. With over 2600 words of research-backed advice, this guide equips you to keep your cold room running smoothly, ensuring efficiency and peace of mind.